General Digital Engineering Solutions for Mining

For decades, mining plant and structures have failed before their design life is reached, sometimes unexpectedly, resulting in costly disruptions and even loss of life. With the aim of extending design life or increasing utilisation, plant designers, suppliers and owners continue to identify different plant operating conditions relative to the original design assumptions. Often, they are unable to understand the knock-on effects of these changes due to lack of accurate data.

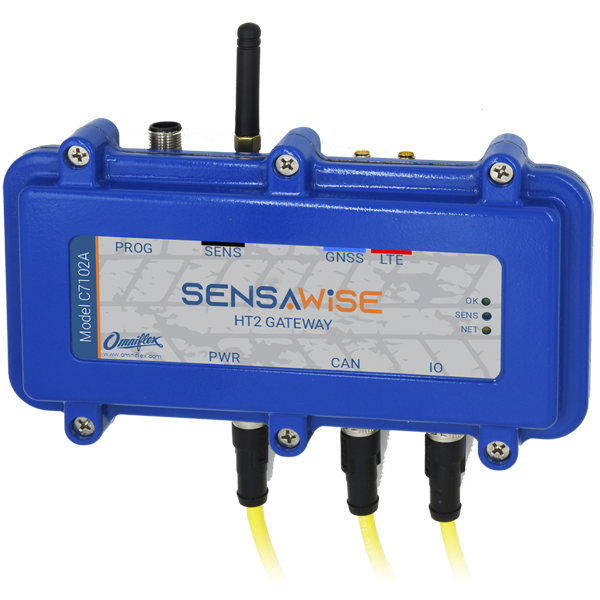

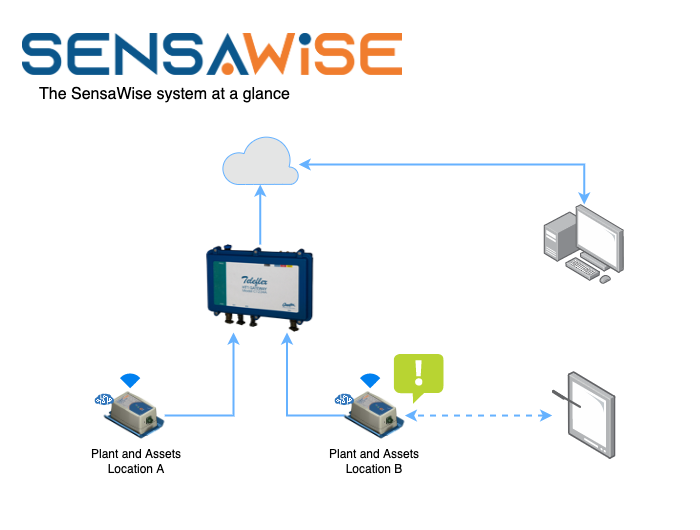

AMOG’s SensaWise solutions bridge the missing link between gathered sensor data and useful operational feedback in a single holistic package. The SensaWise system, which can be installed on existing assets, gathers data which is fed into digital twins of the asset and used to monitor plant and structural response, relative to design, in real time. SensaWise nodes with their edge processing capabilities can identify failures in real-time, monitor and relay data and pro-actively manage alarms and integrate with control systems.

For more information on SensaWise visit sensawise.com

Digital Engineering Solutions for Oversize Rock Detection

Blasting can yield uneven fragmentation of ore, resulting in large pieces of rock called “oversize”. In most instances in open cut mining, oversize material is excavated and transported to the Run of Mine (ROM) area and processing plant by haul trucks. The oversize material then collects in ROM bins or chutes forming blockages as it is too large to feed into the primary crushers. The oversize material impedes the flow of ore, reduces production rates, and can completely block the inlet to the primary crusher causing a shutdown of the plant whilst the blockage is removed. This causes costly delays in production, damages crushing equipment and introduces safety hazards to maintenance personnel when removing the blockages.

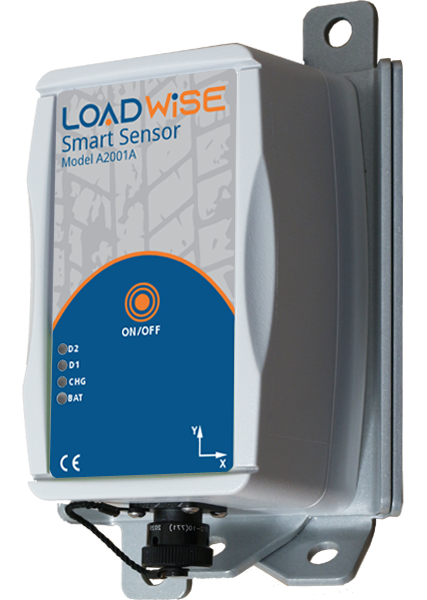

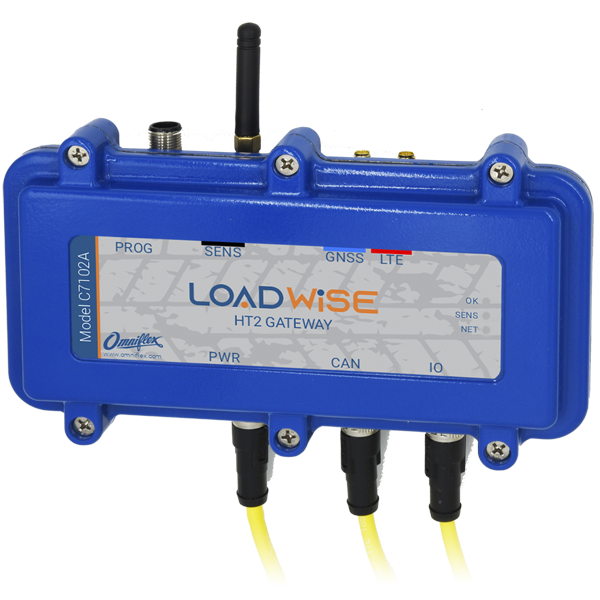

LoadWise is a system designed for data gathering in haul truck applications. The LoadWise system is designed to be scalable such that it can be implemented on a single truck or rolled out across an entire fleet. With the scale of the deployment defined, system components can be retrofitted onto the selected haul truck(s). The system operates in real time to detect and alert when oversized loads are loaded onto the instrumented haul trucks. The outputs from the LoadWise system can assist in improving truck-routing decision-making, which can reduce crusher blockages and optimise crusher throughput.

Though the system’s core functionality is for oversize detection, the system can be extended to perform other functions such as human vibration tolerance monitoring for haul truck operators and road condition monitoring.

For more information on LoadWise visit sensawise.com/loadwise