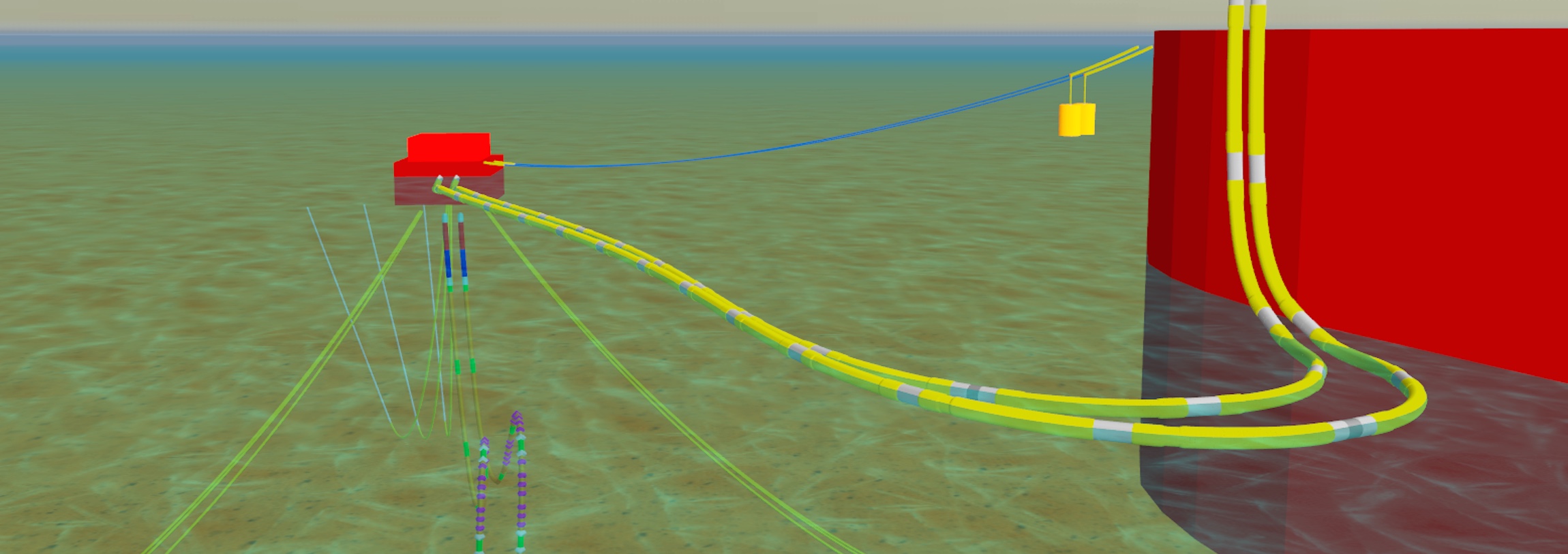

AMOG undertook work on an FSO and sister FSO located in the Persian Gulf off Qatar, exporting product to shuttle tankers via tandem loading. Both FSOs were moored to identical CALM buoys. Each FSO was moored to its CALM buoy by twin hawsers.

For both FSOs, two floating hoses were connected between each FSO and buoy. Crude oil was pumped to each buoy from the adjacent platform via subsea pipeline, subsea hose and then via a floating hose from the buoy to the permanently moored FSO. Water which has settled out in the FSO (produced water) is returned to the platform via the other floating hose, the buoy, subsea hose and subsea pipeline.

Due to integrity issues in first off the buoy hose segments of the produced water hoses, AMOG performed detailed analyses as to the root causes of the behaviour. AMOG subsequently performed numerical simulations of the coupled system (floating hoses, FSO, hawser, CALM buoy, and CALM buoy mooring system) to investigate a range of potential modifications to the floating hose string configuration in order to reduce global loads on the floating hose system.

A number of recommendations were subsequently adopted, including the design of a custom spool piece for the floating hose interface with the CALM buoy.

Detailed floating hose analysis was performed in OrcaFlex, with supporting analyses performed in AQWA.

Floating Hose Design

To further improve the dynamic performance of the floating hose system, AMOG developed a novel floating hose configuration that significantly reduced the loading on the floating hoses. The development of the alternative solution required close collaboration with a hose manufacturer in order to develop hose constructions that could accommodate the proposed configuration.

AMOG assessed the suitability of the proposed configuration by analysing the configuration in survival and operational sea state conditions to predict peak global loads and make comparison with the predicted peak global loads for the existing floating hose arrangement.

In addition AMOG provided the requirements for the floating hose build and tow out, and recommendations for the installation of the floating hose arrangement.

Detailed floating hose analysis was performed in OrcaFlex, with supporting analyses performed in AQWA.