- Mooring lines can fail at any time - the failures are not always obvious but the consequences are significant

- The offshore energy industry averages 4 mooring line failures per year(1,2)

- Ongoing monitoring using a trained and proven system can detect failures earlier so owners and operators can react in time

In order to power society's current and future energy needs, we need to be able to safely and reliably access subsea reserves of oil and gas, and unlock renewable energy sources such as floating offshore wind and wave power. This requires offshore infrastructure held on station by well designed, installed and monitored mooring systems.

What are the consequences of a mooring failure?

At best, a single mooring line failure results in downtime; with deferred production for maintenance impacting the bottom line directly. Shut in of production by a regulator or insurer can have an even broader financial impact. The Gryphon Alpha FPSO’s multi-line failure led to a loss of position and riser system damage resulting in an insurance claim of USD$1billion and over two years of down time(3). The Banff FPSO suffered a multi-line failure leading to significant loss of position, an estimated insured loss of USD$300million, and two and a half years of downtime(4).

Aside from the financial impacts, there is the potential for multi-line mooring failures to result in a loss of station-keeping and potential loss of hydrocarbon containment. After all, a mooring system's primary safety critical role, is to protect the riser system.

The prevalence of multi-line failure becomes a greater concern when arrays of floating wind or wave energy devices are considered. Unlike offshore floating oil and gas facilities that only have one or two assets in field (and thus only one or two mooring systems to consider), arrays of floating wind or wave can contain over one hundred devices, all moored with similar mooring systems. Should a failure or degradation of their mooring systems be found, it could be a catastrophic common mode failure that could result in multiple devices coming free, with cascading effects that may lead the loss of the entire array itself.

How do mooring lines fail?

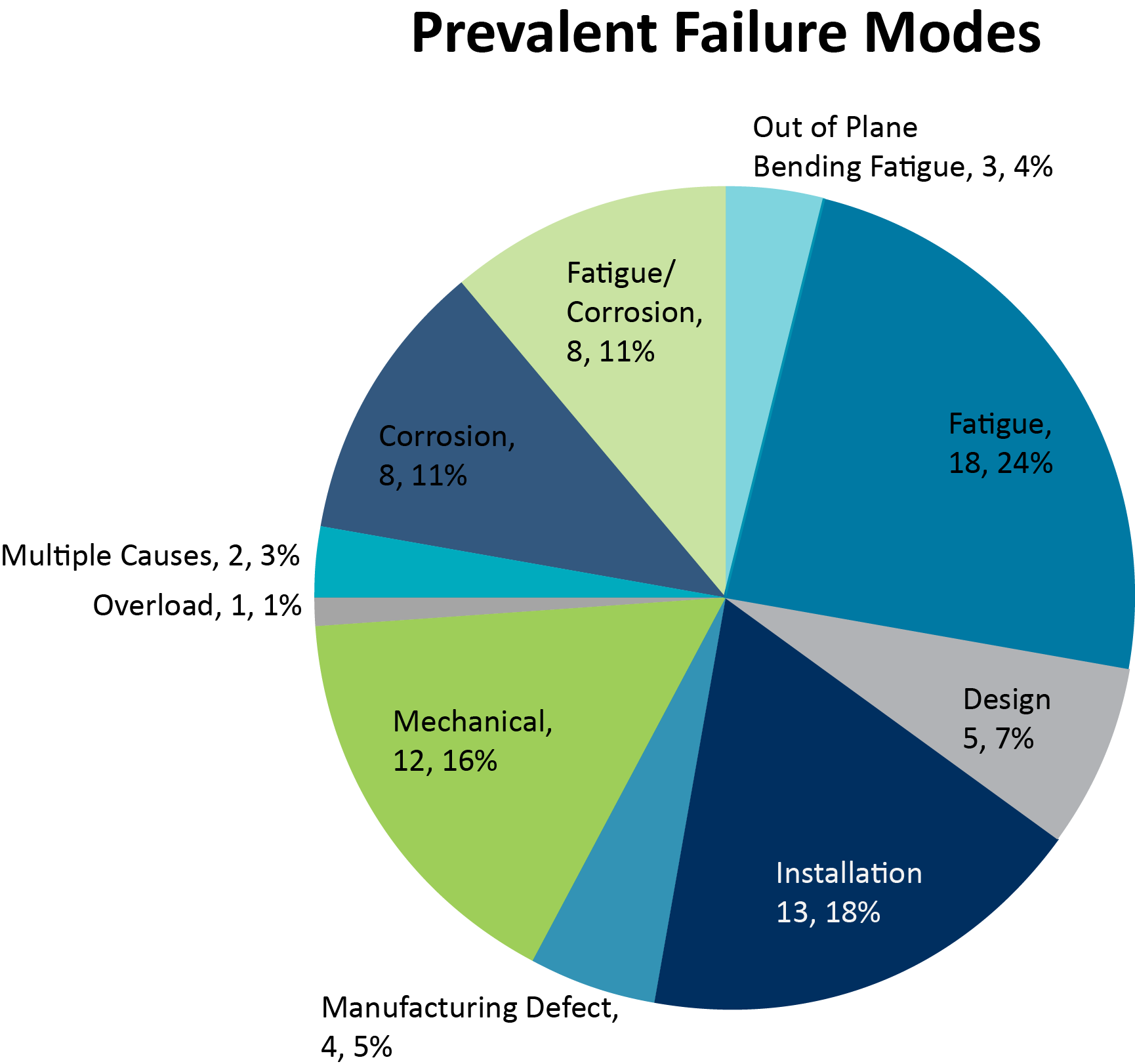

Most facilities are designed for a single mooring leg failure condition, however many failures occur due to a common cause and, as such, multi-line failure on a single facility is not unusual. Further more, most mooring line failures do not occur as a result of a big storm (overload failure) but are attributable to manufacturing or installation anomalies, corrosion, fatigue, mechanical disassembly, or design failures.

The challenge is that all mooring lines in the same system are therefore exposed to the same failure mechanisms, thus increasing the chances of multiple leg failures on the same system.

With over 27 years of experience working in the offshore sector, steering a number of global Joint Industry Projects (JIPs,) and authoring numerous papers on mooring integrity, AMOG set out to develop a mooring integrity solution to provide the level of assurance required by modern FPU owners and operators.

AMOG's Smart Mooring Integrity Checker (SMIC)

From this experience came AMOG’s Smart Mooring Integrity Checker (SMIC) which, rather than relying on purely numerical model inputs, was built and demonstrated on real world data including an actual mooring line failure. Experienced mooring system engineers train sophisticated machine learning models, with the understanding that every mooring system is different: deep vs shallow; spread vs single point; taut, semi-taut and catenary; chain, wire or synthetics, and each subject to varying met-ocean conditions, vessel behaviours, and operational modes.

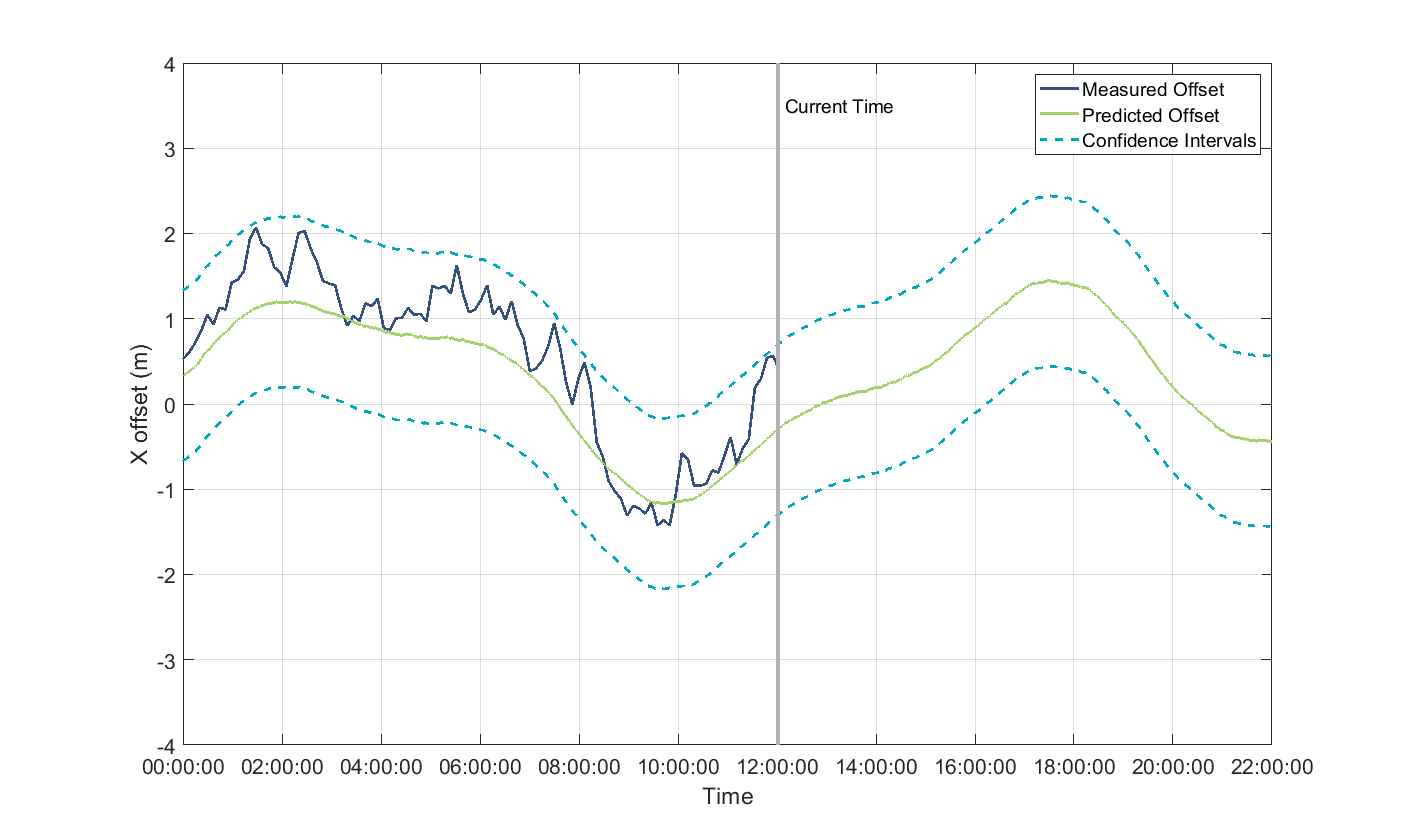

An example chart below illustrates SMIC output data, over time, for offset of a vessel in the east-west direction. Here, the blue line shows measured vessel offsets which are compared to the predictive model (green line), based on environmental data for the site. The light blue dotted lines form the confidence bounds of the predictive model whereby if the measured offsets deviate outside of these bounds, SMIC's ML algorithm will flag a likely change in mooring condition or data fidelity, allowing for operators to make informed decisions with respect to mooring integrity, in a timely fashion (i.e. before the next big storm or before offloading operations).

So why not use one of the existing solutions or methods already out there?

The simple answer is that most of the existing options only work some of the time and are extremely expensive, where installed on commissioning or retrofitted.

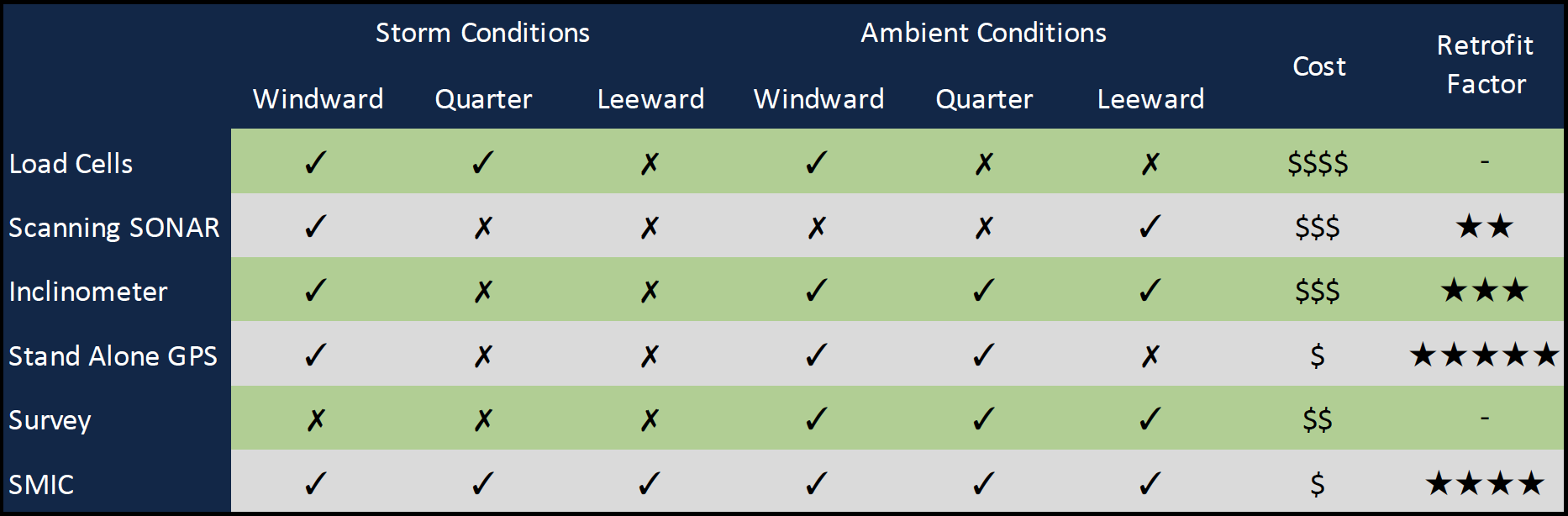

Load cells are traditionally unreliable for moorings; they are either calibrated for the ambient loads in the system and thus saturated in storm conditions, or calibrated for storm conditions and not sensitive enough to detect failures in ambient condition or of mooring lines that are to the leeward (low load) side.

SONAR systems are good at seeing where the leg is, however not for legs that are not at the expected pretension angle.

With an inclinometer, during storm conditions the departure angle of the mooring legs that are quartering or leeward tend to be the same of those legs that have failed (very steep angle).

There are also stand-alone DGPS solutions. With these, it is easy to tell when you drift off station in a storm, but they are not smart enough to tell if other legs have been lost or if a failure occurs prior to a storm. And of course, surveys can also be used – observation is a definitive method for discovering whether a structure has lost a mooring, but observations are costly, are not predictive, and can only be executed in ambient conditions.

Why SMIC?

AMOG's SMIC system turns data already available for the facility into a sophisticated training tool for our proprietary algorithms. If historic data is not available, SMIC is flexible; accepting synthetic data and scenario modelling until the machine learning algorithms have trained on actual facility data.

AMOG SMIC technology uses available data sources, and in most cases requires nothing to be installed subsea so requires very minimal OPEX and no CAPEX. SMIC implementations follow industry best practice when it comes to data security with implementations customisable to adhere to corporate authentications protocols.

The implementation of a mooring monitoring system is an important component of best practice in mooring integrity management. AMOG’s Smart Mooring Integrity Checker can highlight potential problems and allow owners and operators to investigate and respond, potentially increasing uptime, reducing risk, and improving safety. to keeps operations teams, insurers, regulators and duty holders happy.

Click here to read more about SMIC

(1,2) Kilner et al 2015. Based on failure rate of 2.5x10-3 per mooring leg year applied on an assumed population of 190 facilities worldwide, each with an average of 8 mooring lines.

(3) http://www.lloydslist.com/ll/sector/Insurance/article407801.ece

(4) https://www.insidefac.com/articles/103896/qbe-leads-on-300mn-fpso-loss