AMOG and Keen AI develop early crack detection tech to deliver improved safety to mine-sites. The latest development dramatically improves geotechnical risk management of mine open cast pits.

AMOG and Keen AI develop early crack detection tech to deliver improved safety to mine-sites. The latest development dramatically improves geotechnical risk management of mine open cast pits.

With the potential to cause multiple fatalities and stopping a mine for months, pit slope failures are a serious safety and business risk. A recent paper produced by a major miner documented 185 incidences of slope failures at West Australian-based open-pit mines [1] – the challenge is significant.

To manage safety risks, early detection of precursors is vital. They allow mine-sites time to plan and take action to avoid catastrophic events. Mine-sites using early detection better comply with regulatory goals, both with critical risk management and effective safety systems.

AMOG and Keen AI both have extensive experience in early detection. AMOG has developed early detection of large rock blockages, using machine learning applied to haul truck tray vibration signatures and other similar detections using digital information at mines, ports, refineries and petrochemical facilities. Keen AI uses early indicator detection through visual indicators, detected using machine learning of images of electrical systems and more.

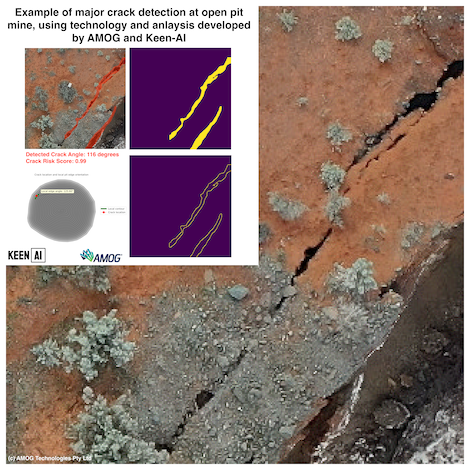

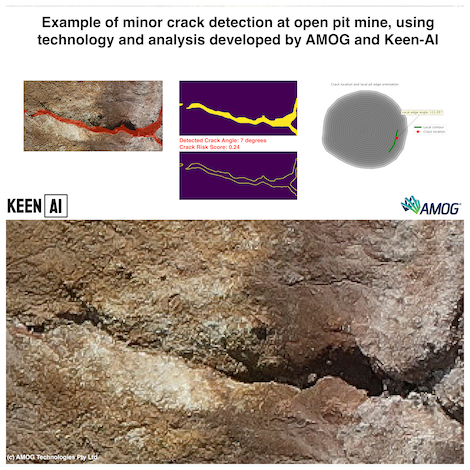

AMOG and Keen AI have developed a pit slope precursor to a failure detection system, with the assistance of Element Geospatial. This system uses drone data, whether collected by the mine site operators or another supplier, to accurately detect and monitor tension and shear cracks associated with pit slope failures.

Using a variety of deep learning and computer vision algorithms Keen AI, with AMOG input, has developed and trialled the detection on several mine pits. It can currently detect tension and shear cracks in drone images with a high degree of accuracy.

Key benefits include:

- Better met regulatory requirements - the detection and monitoring system assists mine sites in meeting the regulatory need to detect, monitor and manage slope instability risks.

- No additional flights needed - drone data becomes useful for digitally assessed risk assessment and there is no need for additional flights

- Less manual reviews - no need for field observations or attempting to detect cracks by manually reviewing hundreds of images - the detection algorithm is more accurate than these techniques and is expected to become even more accurate with time

- Intuitive reporting geared for action - the dashboard that presents results is intuitive and gives users a ranking of risk areas to help prioritise actions

- Change monitoring - once a site's pits are assessed and areas of interest detected, subsequent flight data is used to detect any change, especially when events that can trigger slips occur (such as rainfall, blasting or seismic events, and heavy equipment traffic)

The detection and monitoring system allows geotechnical teams to focus on solutions for problem areas - this quicker response can save lives, time and costs.

Please contact AMOG or Keen AI for more information.

For more information, contact Richard Shedlock (AMOG Perth +61 8 9212 1800) or Hayden Marcollo (AMOG Melbourne +61 3 9542 3700), or the team at Keen-AI.

[1] Goldstein et al, “Framework to predict open pit mine failure runout”, Australian Centre for Geomechanics, Perth, Western Australia, 2023 (DOI https://doi.org/10.36487/ACG_repo/2335_41 )